Alpine Bikes

The highest standards

At Alpine Bikes, our primary goal to exceed the expectations of our customers. We place the utmost importance on the safety, performance, and customer satisfaction of our products. To ensure this, we have implemented a rigorous quality assurance (QA) process that adheres to the highest standards.

Step 1

MATERIAL INSPECTION

To ensure the best possible quality of our carbon fiber products, it is essential to conduct a thorough inspection and verification of all raw materials. This includes carefully checking carbon fiber sheets, resins, and other materials for any defects or inconsistencies.

Step 2

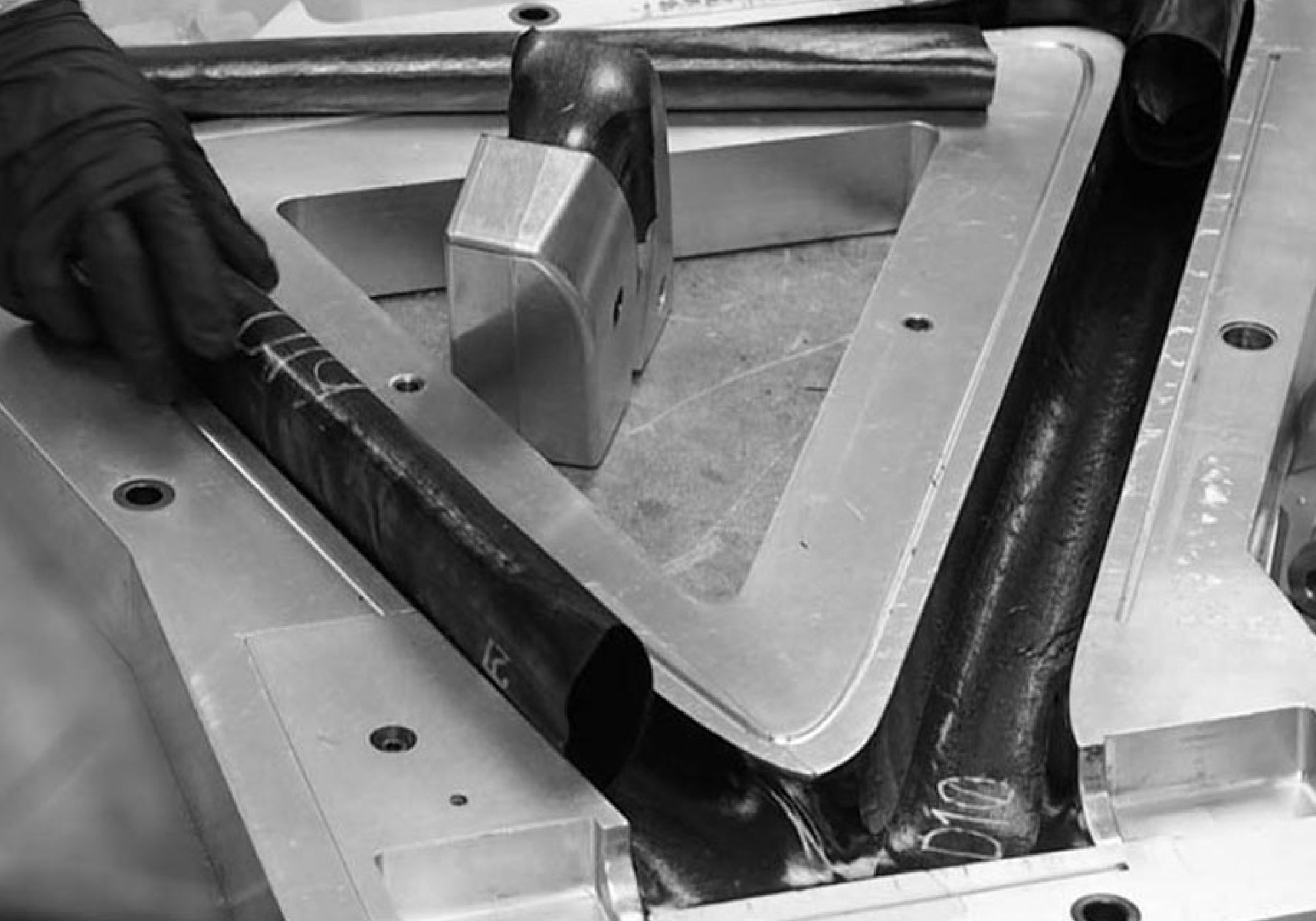

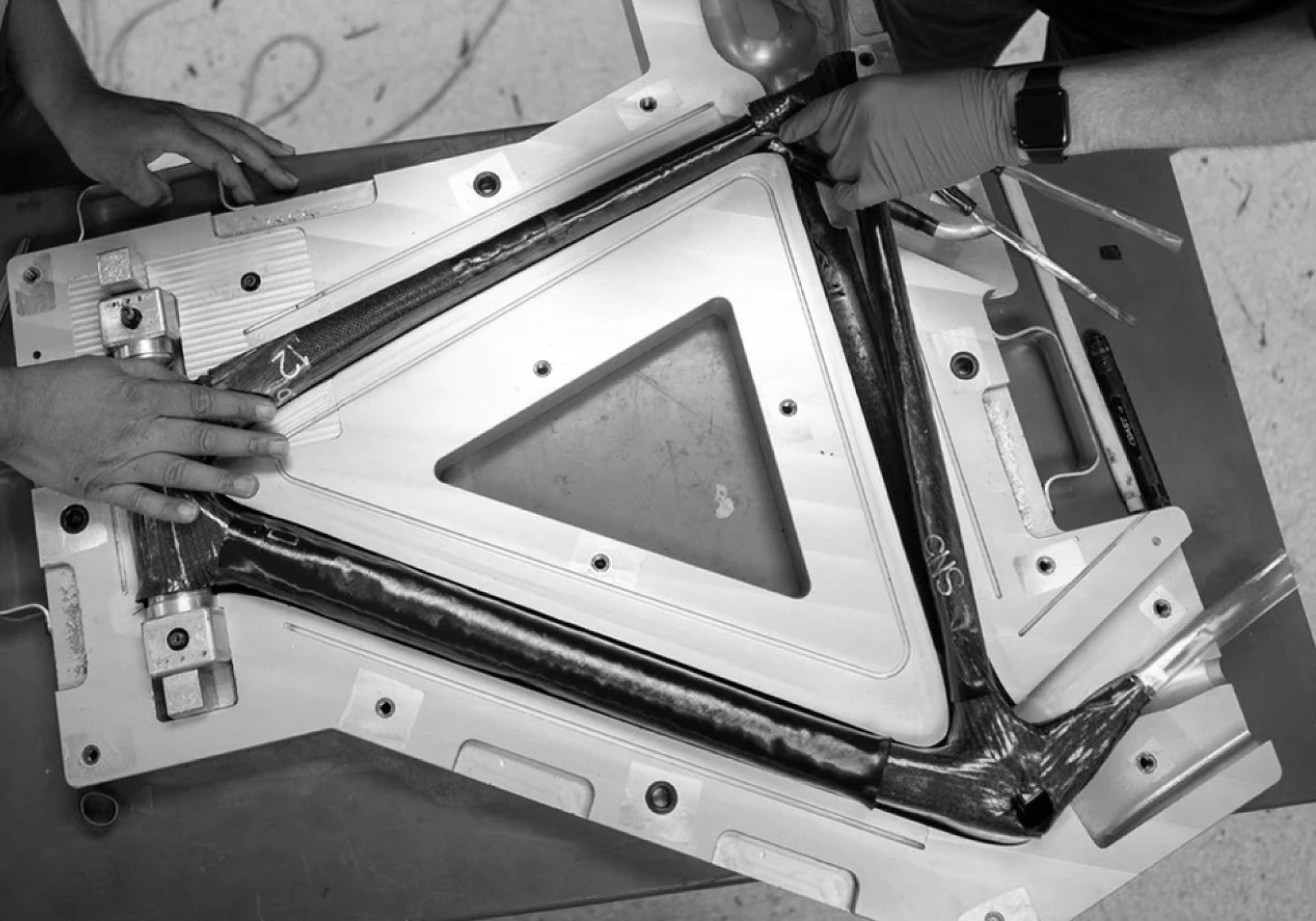

Carbon LAYUP INSPECTION

To ensure the highest level of quality in our products, it is crucial to validate the accuracy of the fiber layup arrangement. By validating the accuracy of the fiber layup arrangement, we can ensure that the fibers are aligned correctly, providing optimal strength and performance.

Step 3

CURING AND POST-CURE INSPECTION

Verify correct curing temperature and time to ensure optimal resin consolidation and bonding.

Inspect for any cosmetic defects, such as wrinkles or air bubbles, and evaluate the overall surface finish.

Step 4

Fatigue testing

Stresses caused by riding forces are simulated by applying 1300 newtons of force to the frame for 100,000 cycles.

To compare, a world-class sprint track cyclist might be able to produce a pedaling force of 1300 newtons.

Step 5

MACHINING AND FINISHING INSPECTION

Check dimensions, tolerances, and surface smoothness after the machining processes.

Ensure proper alignment and fit of components, including forks, seat posts, and handlebars.

Step 6

PACKAGING AND SHIPPING

Review packaging procedures to ensure safe transportation and protection of carbon bikes.

Inspect the overall packaging quality to prevent any damage during transit.

QA TOOLS AND TECHNIQUES

Implement NDT techniques like ultrasonic testing and X-ray testing to detect internal defects without damaging the carbon structure.

Utilize visual inspection to identify surface imperfections, irregularities, or inconsistencies in carbon fiber layers.

Utilize precision measurement tools to verify dimensional accuracy in critical areas such as frame geometry and component fit.

Conduct tests to determine carbon fiber strength, stiffness, and fatigue resistance under extreme mechanical loads.

Have a question?